GM50

Mortar for “gunite”

GM 50 is intended for use as a first (gunite) coat, increasing the adhesion of the next, base coat of plaster. It is applied before plastering walls made of bricks, concrete, cellular lightweight aerated concrete blocks, insulating boards, etc. It can also be used for various repair works in the construction sector. It does not contain lime. Homogeneous, ready-to-mix, industrial product of consistently high quality. It ensures good workability, increased application speed, it is economical and provides excellent results.

Mortar made of high specifications grey cement and strictly selected granulometry and quality of crushed marble, enriched with polymers and other special improving additives. • Classified according to standard EN 998-1: 2016 as a plaster of type: GP, CS IV, Wc2 – Granule size <2.4 mm

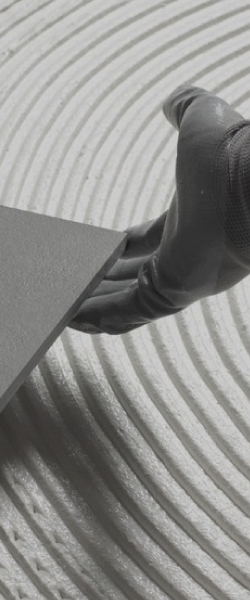

- The substrate must be clean and firm, and it is recommended that it is wetted before application.

- The contents of a bag are mixed with clean water (approximately 5.5-6.0 l/bag) using an electric mixer at low speed or a traditional concrete mixer until a homogeneous mixture is obtained. • It can be applied either in the traditional way (by hand) or with modern plastering machines.

- The plaster should be applied evenly, completely covering the masonry and leaving a rough surface. It is recommended to be wetted for the first two days.

- The base or main coat of plaster should be applied after two or three days. Depending on the climatic conditions, this period should be extended.

- During the application stage, the temperature should be between +5 oC and +35 oC.

Ready-to-mix plasters should not be applied directly onto plaster walls or gypsum mortars, except under the responsibility of the user and only if an acrylic primer has been applied beforehand. The overdosage of water reduces the expected quality of the products. Ready-to-mix plasters contain cement which is classified as an irritant. Consult the safety instructions and precautions listed in the Material Safety Data Sheet of the product.

In bags of 25 kg, on pallets. • In a dry place where frost does not form, for 12 months from the date of production, in unopened bags

Approximately 5 kg/m2, depending on the type of substrate and its preparation.

Specifications: EN 998-1:12016

| Granule size | 0.0-2.4 mm |

| Adhesion | 2.3 N/mm² |

| Resistance to bending | 3.5 N/mm22 |

| Resistance to compression | 9.2 N/mm22 |

| Apparent dry mortar density | 1690 kg/m3 |

| Consumption | 5 kg/m2 |

| Capillary water absorption (Cm) | 0.05 kg/m2. min0.5 |

GM 50 mortar contains cement which is classified as an irritant. Consult the safety instructions and precautions listed in the Material Safety Data Sheet of the product. Although the specifications and instructions presented in this bulletin have been prepared to the best of our skills, knowledge and experience, they should be taken as indicative results and require verification after many applications. Users to whom this product is addressed should verify its suitability for the intended application. The end user is responsible for any result of the use of the product.