Product Categories

Everything you need for repairs or new constructions

FL100 ST BIOPANOPLY

In stock

FL100 ST WOOL

In stock

INSULATION BOARDS

In stock

HYDOM METAL CONNECTOR

In stock

BIOPLASTER

In stock

Paste & coating

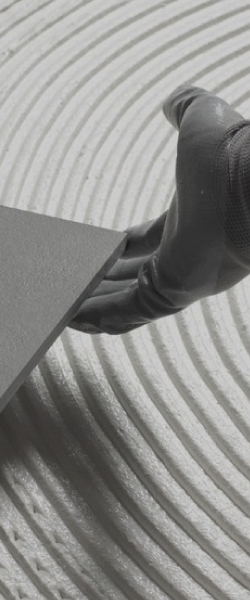

Installation of Lining Materials

Our projects

Work Samples

BIOPLASTER

Acrylic, waterproof, colored decorative plaster in paste form (White or colored)

GRANULOMETRIES OF DECOR: FINE (1.0 mm) / STANDARD (1.3 mm) / THICK (1.6 mm) GRANULOMETRIES OF GRAFIATO: STANDARD (1.3 mm) / ROUGH (2.4 mm)

BIOPLASTER is a colored, pasty, acrylic plaster, ready to use, in a DÉCOR & GRAFIATO look. Suitable for outdoor and indoor applications. It is used as a top coat on substrates such as base or single coat plasters, concrete, plasterboards, cement boards, etc. It is ideal as a top coat for external thermal insulation systems. It complies with: EAD 040083-00-0404, ETA 20/0778 - 20/0699 - 19/0472, for the BIOPANOPLY (EPS, XPS, WOOL) external thermal insulation systems of MARMODOM as a decorative finishing plaster. It ensures full water repellency and eliminates the risk of cracking. No painting of the plastered surfaces is required. Homogeneous, ready-to-use, industrial product of consistently high quality. It ensures good workability, increased application speed, it is economical and provides excellent results.EASYROLL

Flexible, waterproof, colored, acrylic plaster applied by a roller

EASYROLL is a colored, ready-to-use acrylic plaster in paste form for exterior and interior applications. It is used as a top coat plaster. It has an advantage over similar products because it is applied with a roller, like common paint. The reduced consumption and speed of application are also key advantages, as well as the fact that it does not require finishing. It is applied over substrates such as base coat plasters, concrete, plasterboards, cement boards, etc. It ensures full water repellency, covers existing cracks and eliminates the risk of new cracks. No painting of the plastered surfaces is required. It is ideal for final coating on external thermal insulation. It complies with: EAD 040083-00-0404, ETA 20/0778 - 20/0699, for the external thermal insulation systems BIOPANOPLY EPS and WOOL of MARMODOM. Homogeneous, ready-to-use, industrial product of consistently high quality. It ensures good workability, increased application speed, it is economical and provides excellent results.SILICONE PLASTER

Silicone, water vapor permeable, colored, decorative plaster

GRANULOMETRIES OF DECOR: FINE (1.0 mm) / STANDARD (1.3 mm) GRANULOMETRIES OF GRAFIATO: STANDARD (1.3 mm)

SILICONE PLASTER is a colored, silicone, water vapor permeable and waterproof plaster in the form of a paste, ready-to-use on DÉCOR & GRAFIATO facades. Suitable for outdoor and indoor applications. It is used as a top coat on substrates such as base or single coat plasters, concrete, plasterboards, cement boards, etc. It is ideal as a top coat for external thermal insulation systems. It complies with: EAD 040083-00-0404, ETA 20/0778 and ETA 20/0699, for MARMODOM's BIOPANOPLY EPS and WOOL external thermal insulation systems as a decorative finishing plaster. It ensures full water repellency and at the same time high water vapor permeability and breathability of the structural elements, thus reducing to a minimum the possibility of mold growth. It eliminates the risk of cracking. No painting of the plastered surfaces is required. Homogeneous, ready-to-use, industrial product of consistently high quality. It ensures good workability, increased application speed, it is economical and provides excellent results.

BIOPLASTER

Acrylic, waterproof, colored decorative plaster in paste form (White or colored)

GRANULOMETRIES OF DECOR: FINE (1.0 mm) / STANDARD (1.3 mm) / THICK (1.6 mm) GRANULOMETRIES OF GRAFIATO: STANDARD (1.3 mm) / ROUGH (2.4 mm)

BIOPLASTER is a colored, pasty, acrylic plaster, ready to use, in a DÉCOR & GRAFIATO look. Suitable for outdoor and indoor applications. It is used as a top coat on substrates such as base or single coat plasters, concrete, plasterboards, cement boards, etc. It is ideal as a top coat for external thermal insulation systems. It complies with: EAD 040083-00-0404, ETA 20/0778 - 20/0699 - 19/0472, for the BIOPANOPLY (EPS, XPS, WOOL) external thermal insulation systems of MARMODOM as a decorative finishing plaster. It ensures full water repellency and eliminates the risk of cracking. No painting of the plastered surfaces is required. Homogeneous, ready-to-use, industrial product of consistently high quality. It ensures good workability, increased application speed, it is economical and provides excellent results.EASYROLL

Flexible, waterproof, colored, acrylic plaster applied by a roller

EASYROLL is a colored, ready-to-use acrylic plaster in paste form for exterior and interior applications. It is used as a top coat plaster. It has an advantage over similar products because it is applied with a roller, like common paint. The reduced consumption and speed of application are also key advantages, as well as the fact that it does not require finishing. It is applied over substrates such as base coat plasters, concrete, plasterboards, cement boards, etc. It ensures full water repellency, covers existing cracks and eliminates the risk of new cracks. No painting of the plastered surfaces is required. It is ideal for final coating on external thermal insulation. It complies with: EAD 040083-00-0404, ETA 20/0778 - 20/0699, for the external thermal insulation systems BIOPANOPLY EPS and WOOL of MARMODOM. Homogeneous, ready-to-use, industrial product of consistently high quality. It ensures good workability, increased application speed, it is economical and provides excellent results.SILICONE PLASTER

Silicone, water vapor permeable, colored, decorative plaster

GRANULOMETRIES OF DECOR: FINE (1.0 mm) / STANDARD (1.3 mm) GRANULOMETRIES OF GRAFIATO: STANDARD (1.3 mm)

SILICONE PLASTER is a colored, silicone, water vapor permeable and waterproof plaster in the form of a paste, ready-to-use on DÉCOR & GRAFIATO facades. Suitable for outdoor and indoor applications. It is used as a top coat on substrates such as base or single coat plasters, concrete, plasterboards, cement boards, etc. It is ideal as a top coat for external thermal insulation systems. It complies with: EAD 040083-00-0404, ETA 20/0778 and ETA 20/0699, for MARMODOM's BIOPANOPLY EPS and WOOL external thermal insulation systems as a decorative finishing plaster. It ensures full water repellency and at the same time high water vapor permeability and breathability of the structural elements, thus reducing to a minimum the possibility of mold growth. It eliminates the risk of cracking. No painting of the plastered surfaces is required. Homogeneous, ready-to-use, industrial product of consistently high quality. It ensures good workability, increased application speed, it is economical and provides excellent results.MW200

Single coat plaster

MW200 is used as a single coat plaster on interior and exterior surfaces. It is also suitable for various repair works. Homogeneous, ready-to-mix, industrial product of consistently high quality. It ensures good workability, increased application speed, it is economical and provides excellent results.DECOPLASTER DECOR

Water-repellent top coat plaster

GRANULOMETRIES: FINE / STANDARD

DECOPLASTER DECOR is a decorative top coat plaster which is mainly used for exterior, but also for interior applications. It complies with: EAD 040083-00-0404, ETA 20/0778 - 20/0699, in the context of MARMODOM’s external thermal insulation systems BIOPANOPLY (EPS / WOOL), as a final decorative plaster on the external render of the thermal insulation boards ("adhesive/mesh"). It is applied on top of the main layer plaster or the one layer plaster, and after its application, no painting of the plastered surfaces is required. Homogeneous, ready-to-mix, industrial product of consistently high quality. It has excellent mechanical characteristics, excellent adhesion and resistance to humidity and frost, and increased resistance to cracking. It ensures good workability, increased application speed, it is economical and provides excellent results.TC500 FINE

Top coat plaster

TC500 FINE is a decorative thin coat plaster and it is used as a top coat on interior and exterior surfaces. It is applied on top of the base coat plaster, and after its application, no painting of the plastered surfaces is required. Homogeneous, ready-to-mix, industrial product of consistently high quality. It ensures good workability, increased application speed, it is economical and provides excellent results.Nothing Found

Apologies, but no results were found. Perhaps searching will help find a related post.